Workers in digital imaging and publishing use color management to achieve consistency throughout a workflow. The goal is to preserve the quality and accuracy of an image from capture to final reproduction. Each device in the workflow supports a different color space. The available color management systems profile the gamut capabilities of each device, and then limit the working color space to the gamut that is shared by all of them.

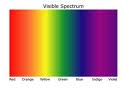

The workflow used by color metrologists is different. Many labs employ more  than one instrument to measure color or appearance and to assure quality control. Here we'll focus on measurements of spectral reflectance factors ("SRF") for uniformly colored samples. A spectrophotometer is used to measure SRF data throughout the visible spectrum, which extends from 400 - 700 nm.

than one instrument to measure color or appearance and to assure quality control. Here we'll focus on measurements of spectral reflectance factors ("SRF") for uniformly colored samples. A spectrophotometer is used to measure SRF data throughout the visible spectrum, which extends from 400 - 700 nm.

Different instruments may not output the same SRF data based on measurements of the same transfer standard. In this situation tests of inter-instrument agreement may be used to measure the consistency between the participating instruments. Depending on the outcome of these tests, color management may be required to enable the meaningful sharing of SRF data.

Inter-instrument agreement cannot be achieved unless the test instruments employ the same geometry. See Color Geometry: A Matter of Degrees (another post within this blog) for a discussion of geometry.

In printing and the graphic arts metrologists who use sphere-based instruments employ the (d/8°) diffuse hemispherical specular-excluded ("SCE") geometry. Others prefer the (0°/45°) or (45°/0°) bi-directional geometry. Because gloss is important in the manufacture of paints and architectural ceramics, in those industries metrologists prefer the (t/8°) total hemispherical specular-included ("SCI") geometry, although certain segments of the coatings industry, namely coil coating, have standardized on 45°/0° geometry.

Among comparable instruments that use the same geometry, other factors may lead to differences in the measured SRF data. Before listing these factors, we stipulate that the instruments to be compared are maintained in good working order, and that suitable procedures are used to achieve consistent sample quality and to measure accurate SRF data.

Differences in the SRF values measured by comparable instruments may result from the following types of wavelength-dependent error: (1) Photometric scale. (2) Wavelength scale. (3) Bandwidth.

The standard multivariate regression procedure that is used to characterize these errors was described in the open literature more than 20 years ago. In a complementary approach, during 2009 the author developed transfer standards that are optimized for detecting these errors. For more information see Color Measurement Accuracy: Diagnostic Procedures (another post within this blog).

The multivariate regression procedure detects and measures the following errors: (1) Photometric zero (black point). (2) Photometric linear scale (100% reflectance line). (3) Photometric nonlinear scale. (4) Wavelength scale. (5) Bandwidth. This method cannot compensate for differences in instrument geometry, or for the errors that result from thermochromism or lateral diffusion. For a discussion of translucency see Color Measurement Accuracy: Translucent Materials (another post within this blog).

CyberChrome's OnColor Profiler® profiling system can analyze the errors listed above on most of the instruments that are in use today. This system includes software and 32 reduced-translucency transfer standards that are optimized for profiling. The OnColor Profiler® software compares the SRF data measured on each test instrument with data from a master instrument. The software generates correlation coefficients, or correction factors, that may be used to improve inter-instrument agreement with the master instrument. See How to improve Inter-instrument Agreement with Instrument Profiling (another post within this blog).

The author of this article is John W. Root Ph.D. of Mt. Baker Research who can be reached via email at jackroot@mtbakerresearch.com.